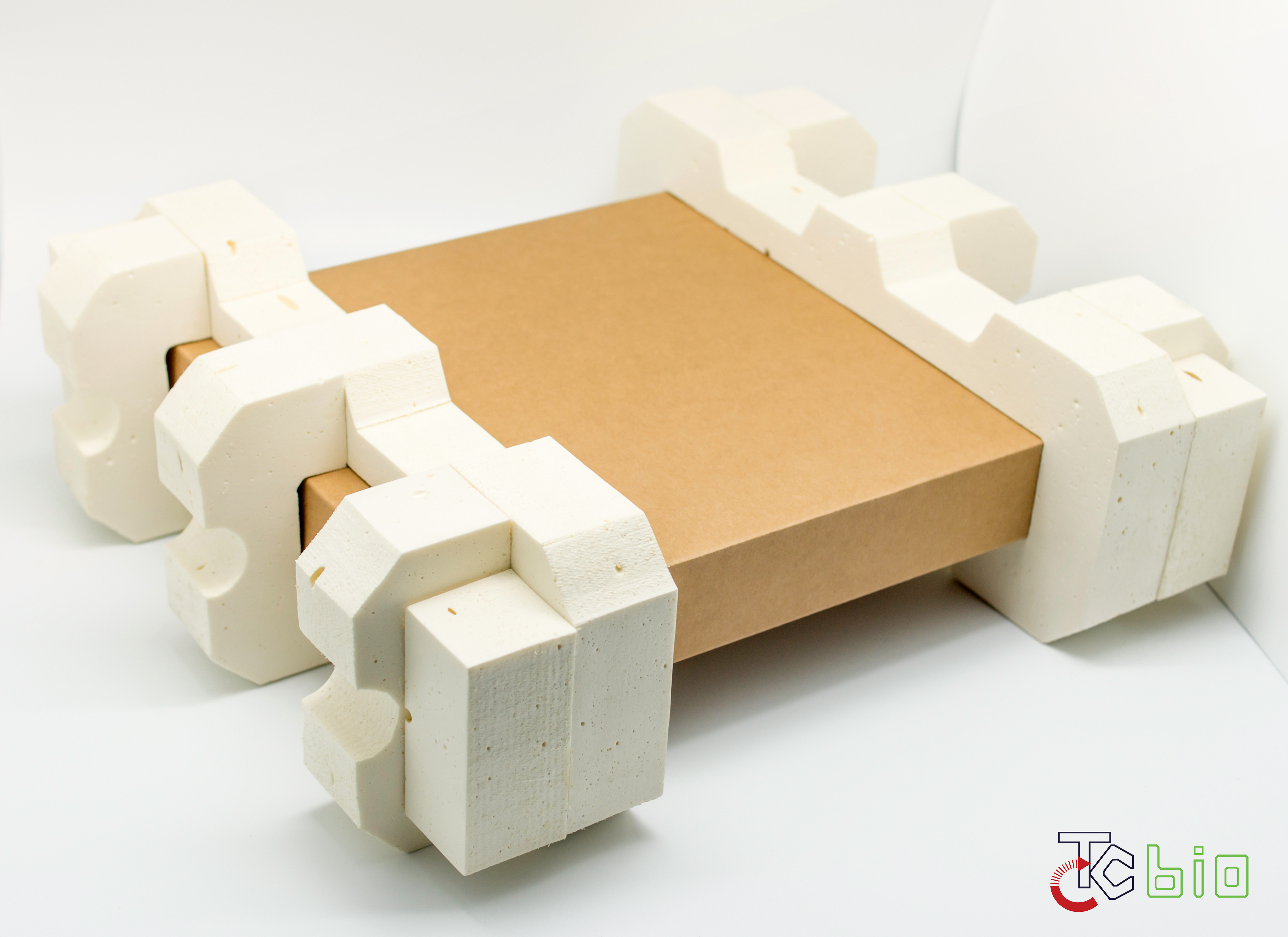

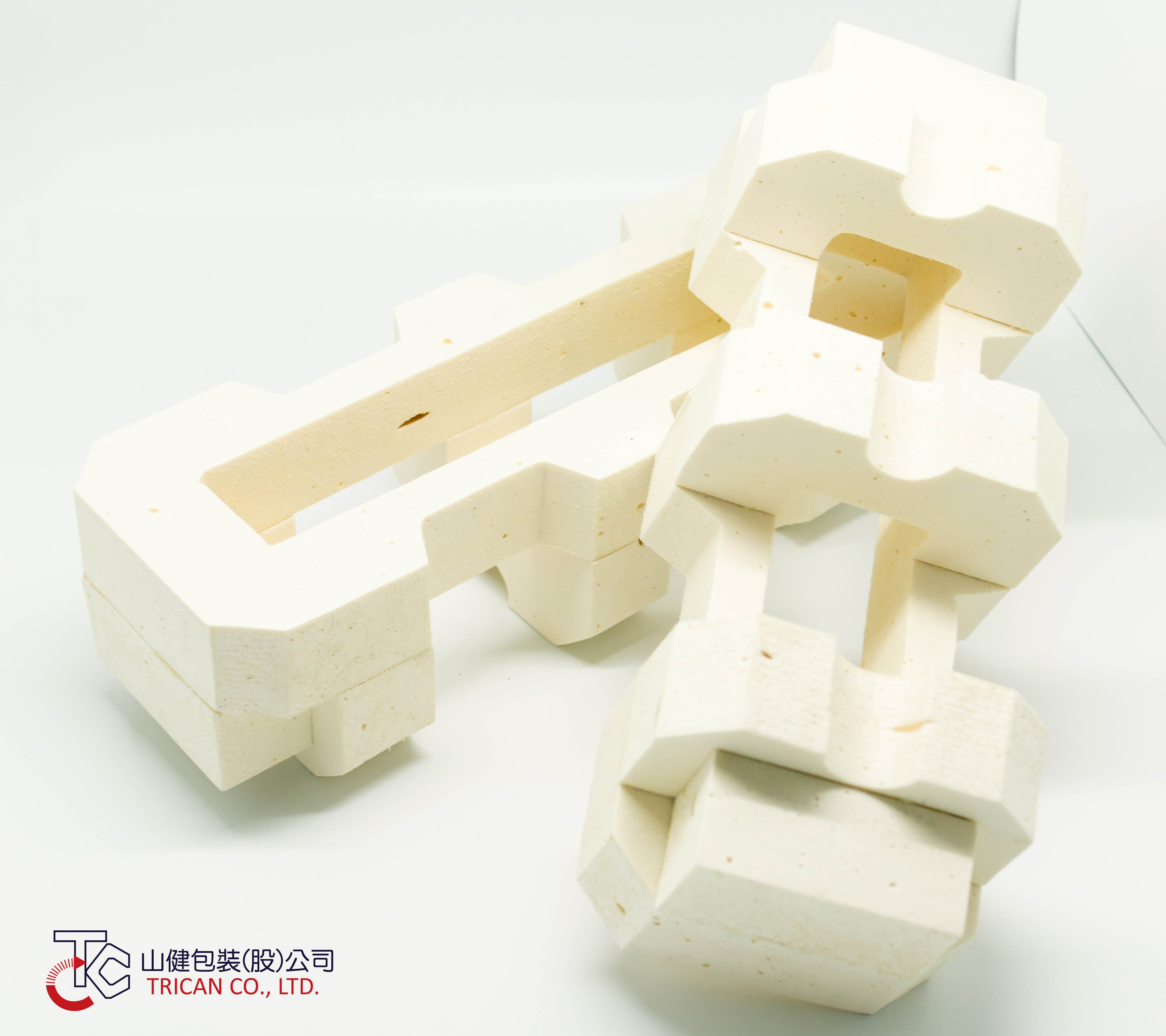

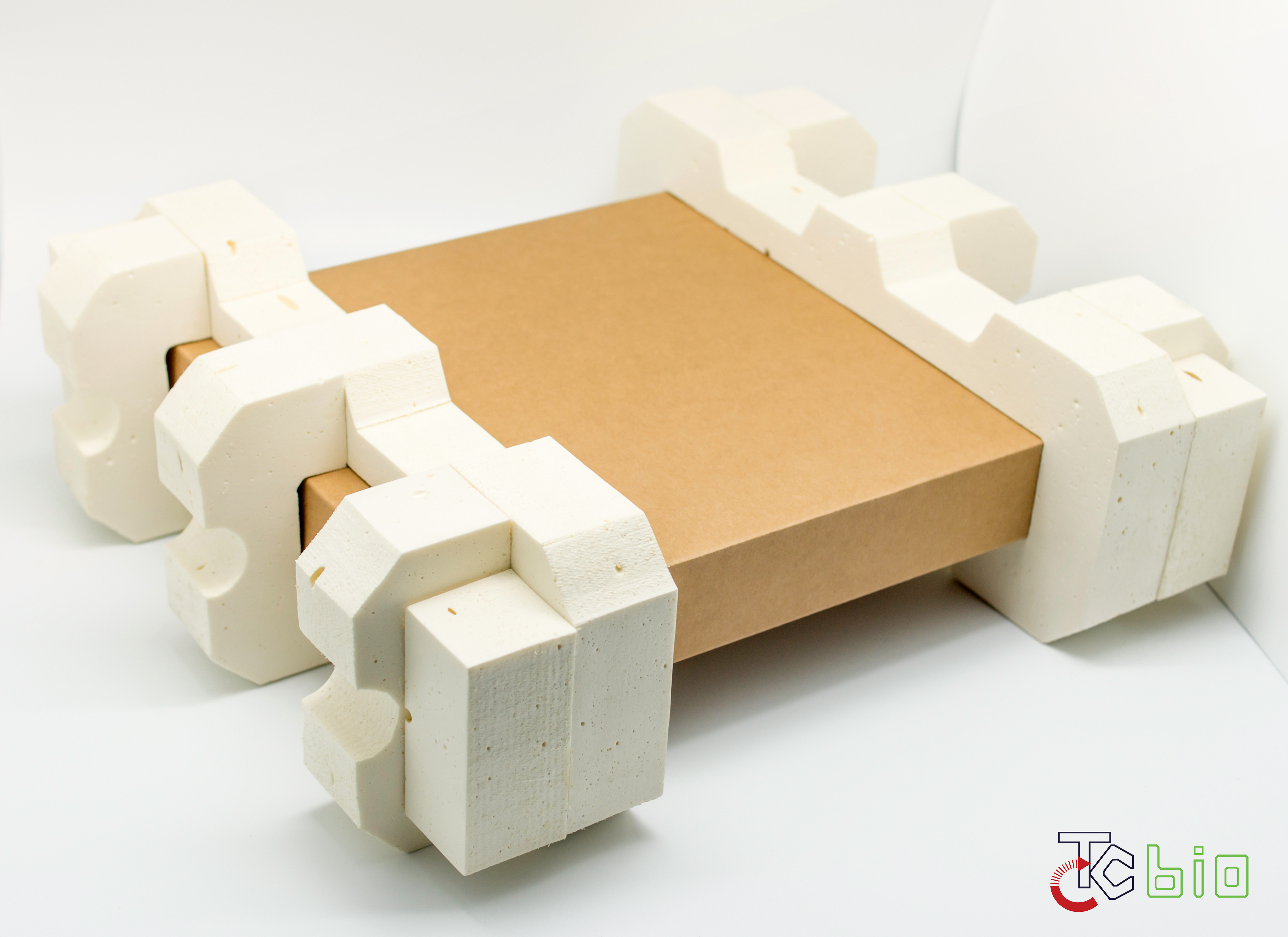

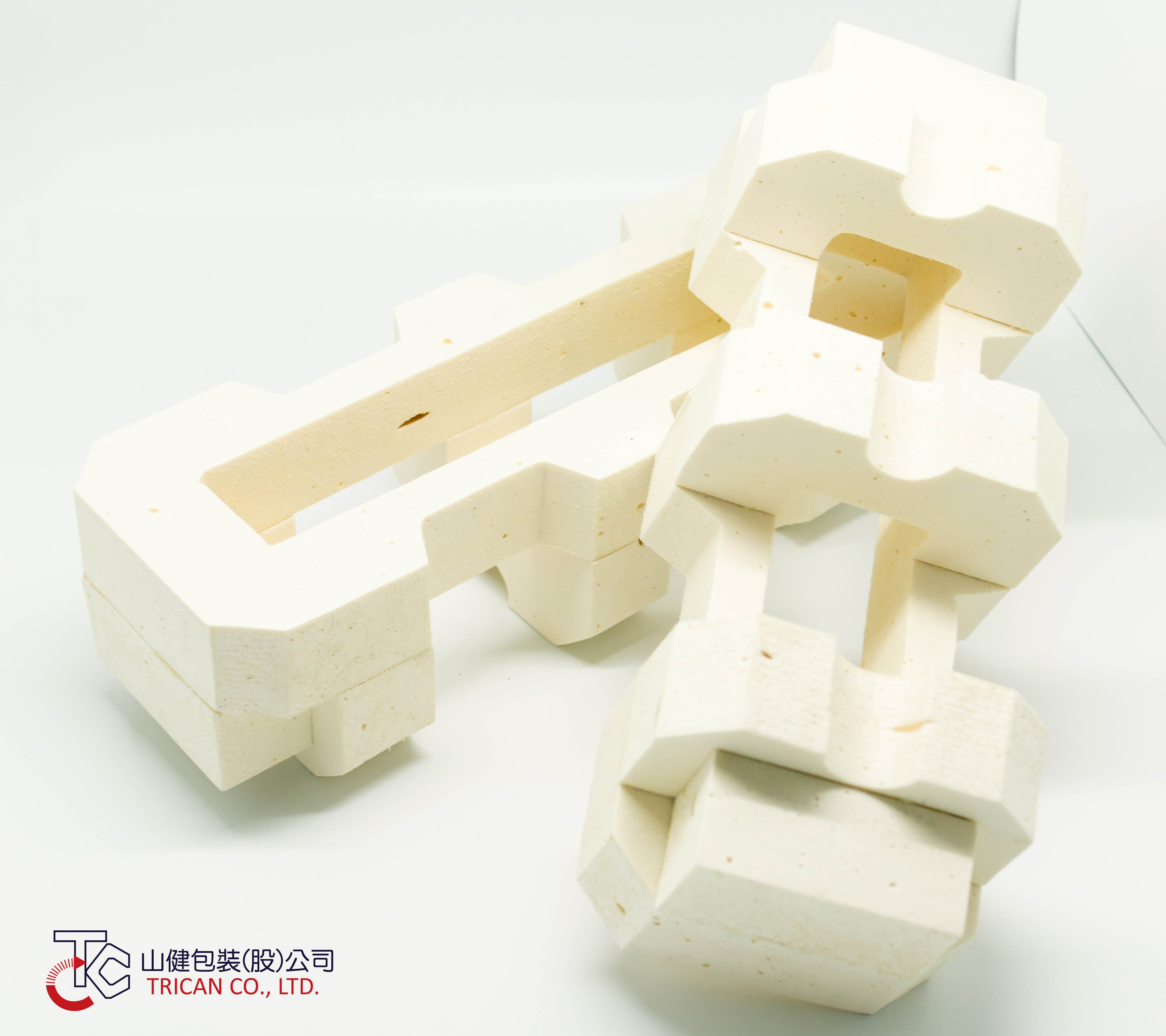

bio-cushion

Biomass foam material

Trican Co., Ltd.Trican bio foam is an innovative, environmentally friendly material which is made of renewable materials, such as plant fiber, rice husk, and starch. The bio-cushion manufacturing process is more energy-efficient than traditional plastic foams and LCA analysis indicates its CO₂ emissions are only half that of plastic foam. It has better vibration absorption than traditional plastic foam due to less compression set values. The foam cell can be used in different applications, e.g. product packaging, insulating and cushion materials. It’s recyclable and is able to be completely reused.