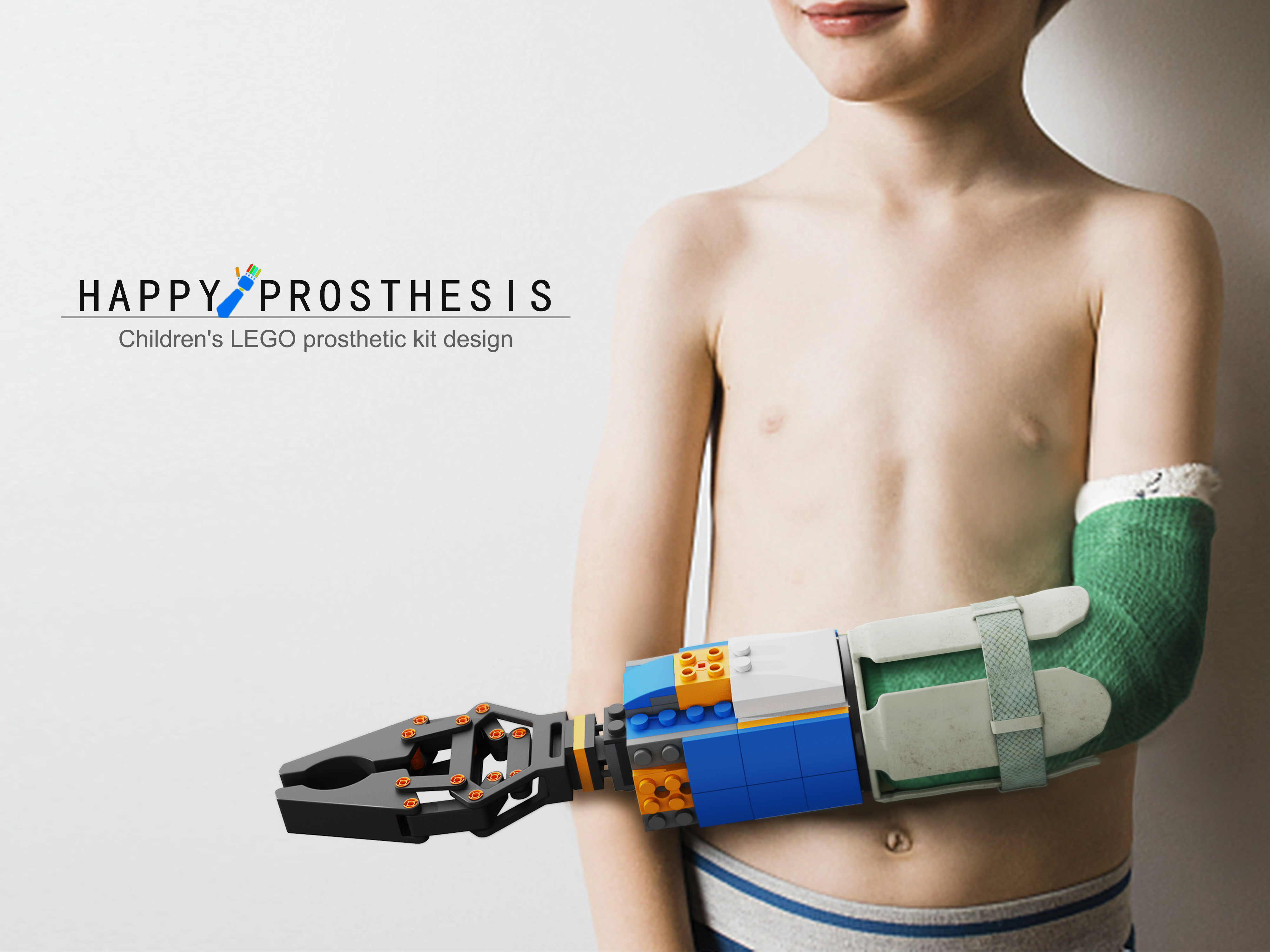

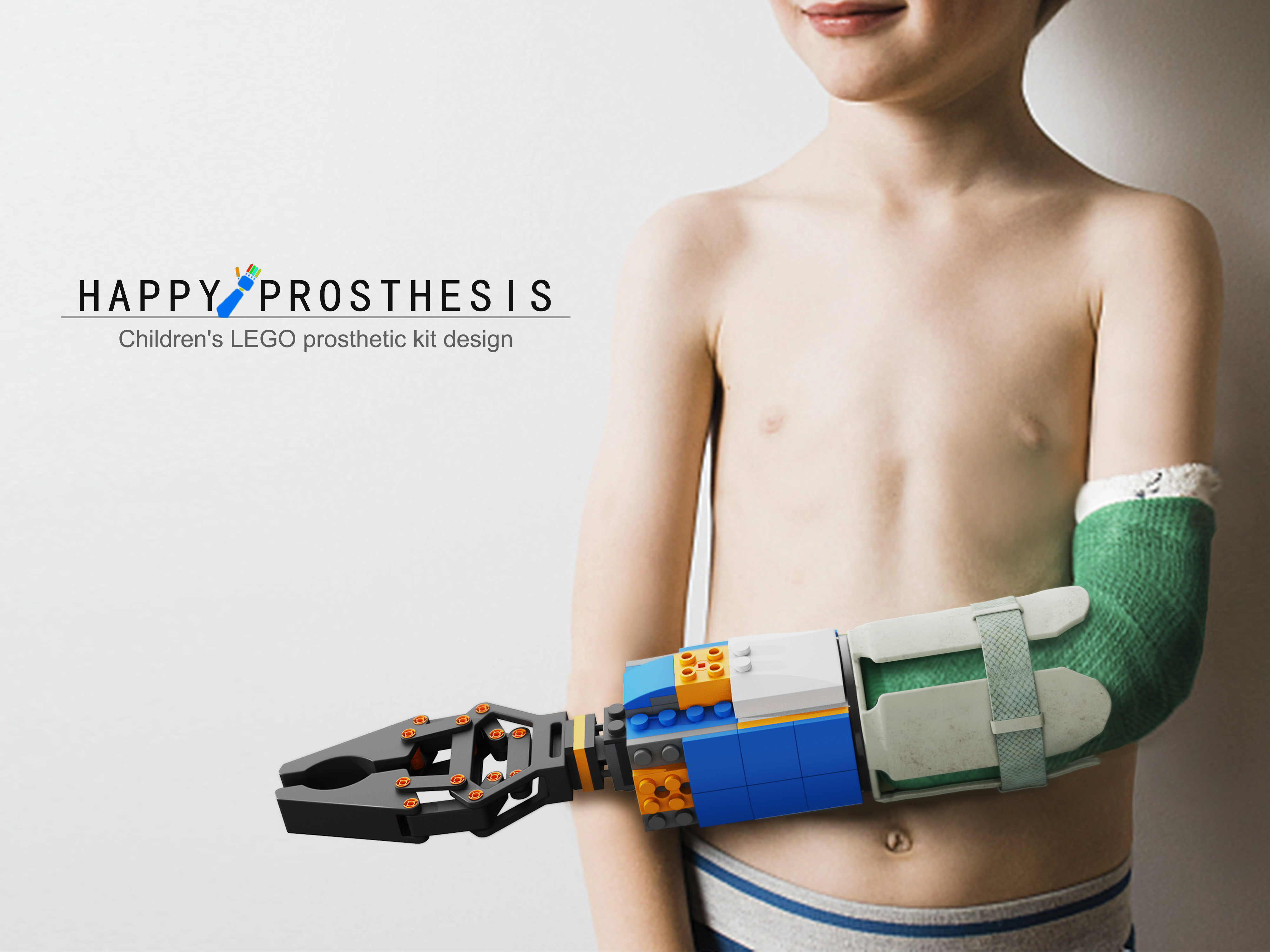

Happy Prosthesis

LEGO prosthesis

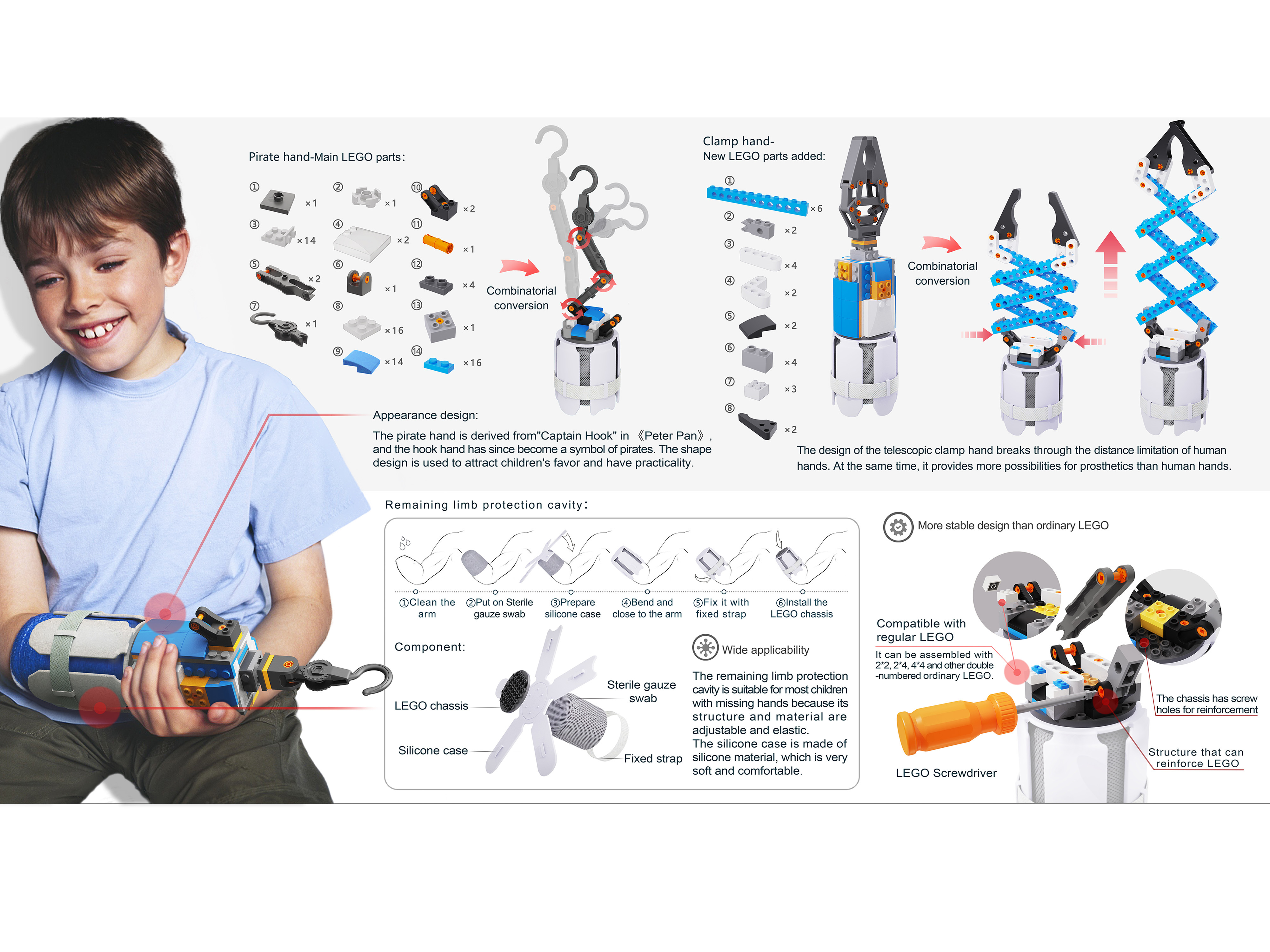

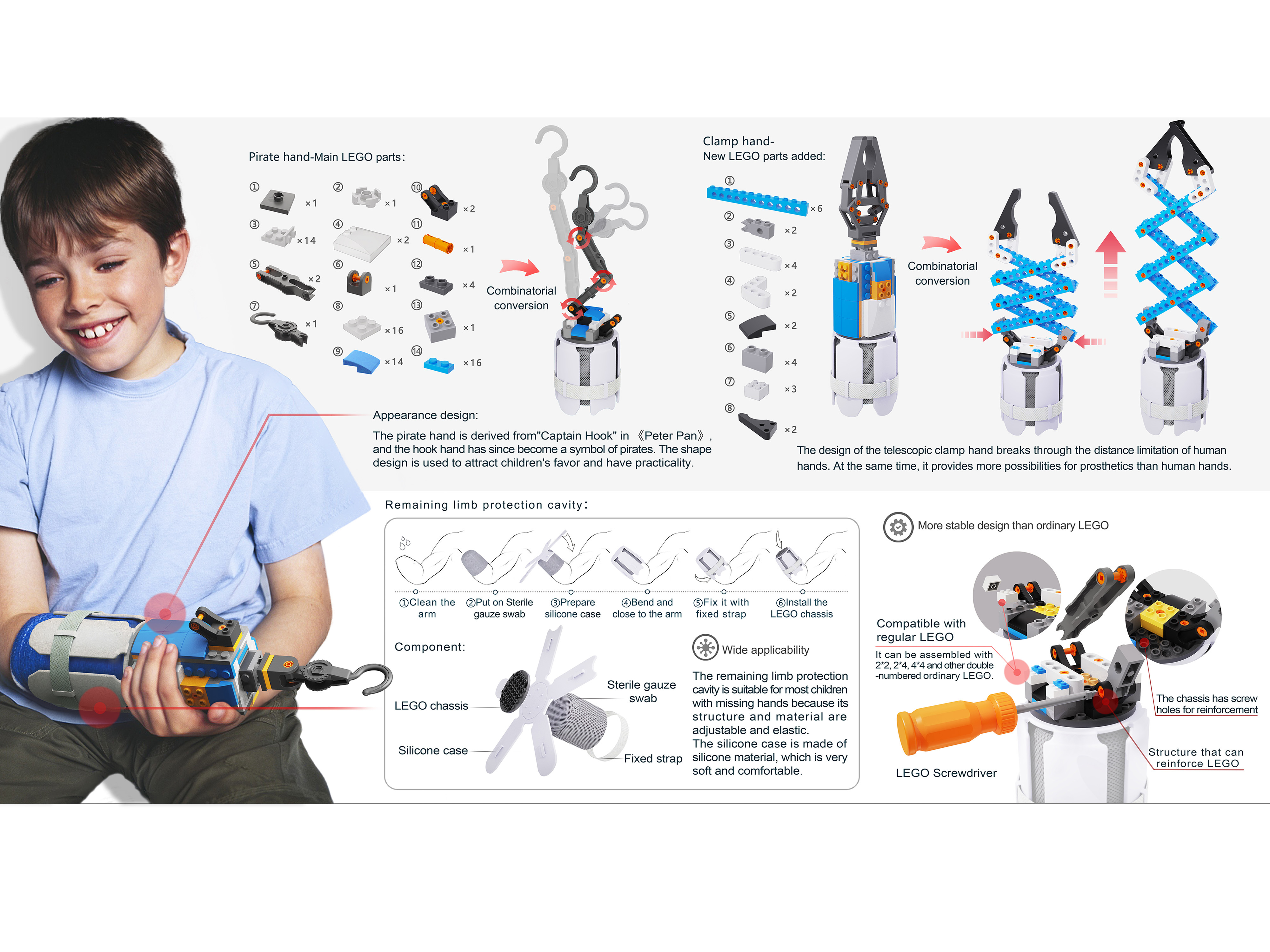

More than 100 million children worldwide live with disabilities, and many of them cannot afford the necessary medical intervention. "Happy Prosthesis" is a LEGO product explicitly designed for child amputees. It includes specific LEGO parts and a protective cavity that wraps the residual limb. Due to the uniform size of LEGO, production and maintenance costs are minimal. The protective cavity is made of silicone material, which can meet the size requirements of different users, thus supporting mass production. At the same time, the fun inherent in a LEGO product can help to reduce a child's resistance to prosthetics.

This product design confronts the reality that more than 100 million children around the world are missing one or more limbs, often as a result of war or natural disasters. Most disability aids provide variable mechanical functions, but the price is often too high for poor children. To solve this problem, the designer creatively applied the LEGO block assembly method. The design of this product was highly focused and effort-intensive.

UNIVERSITYNational Taiwan University of Science and Technology

Tainan, TWChen-Rao Zhong

National Taiwan University of Science and Technology