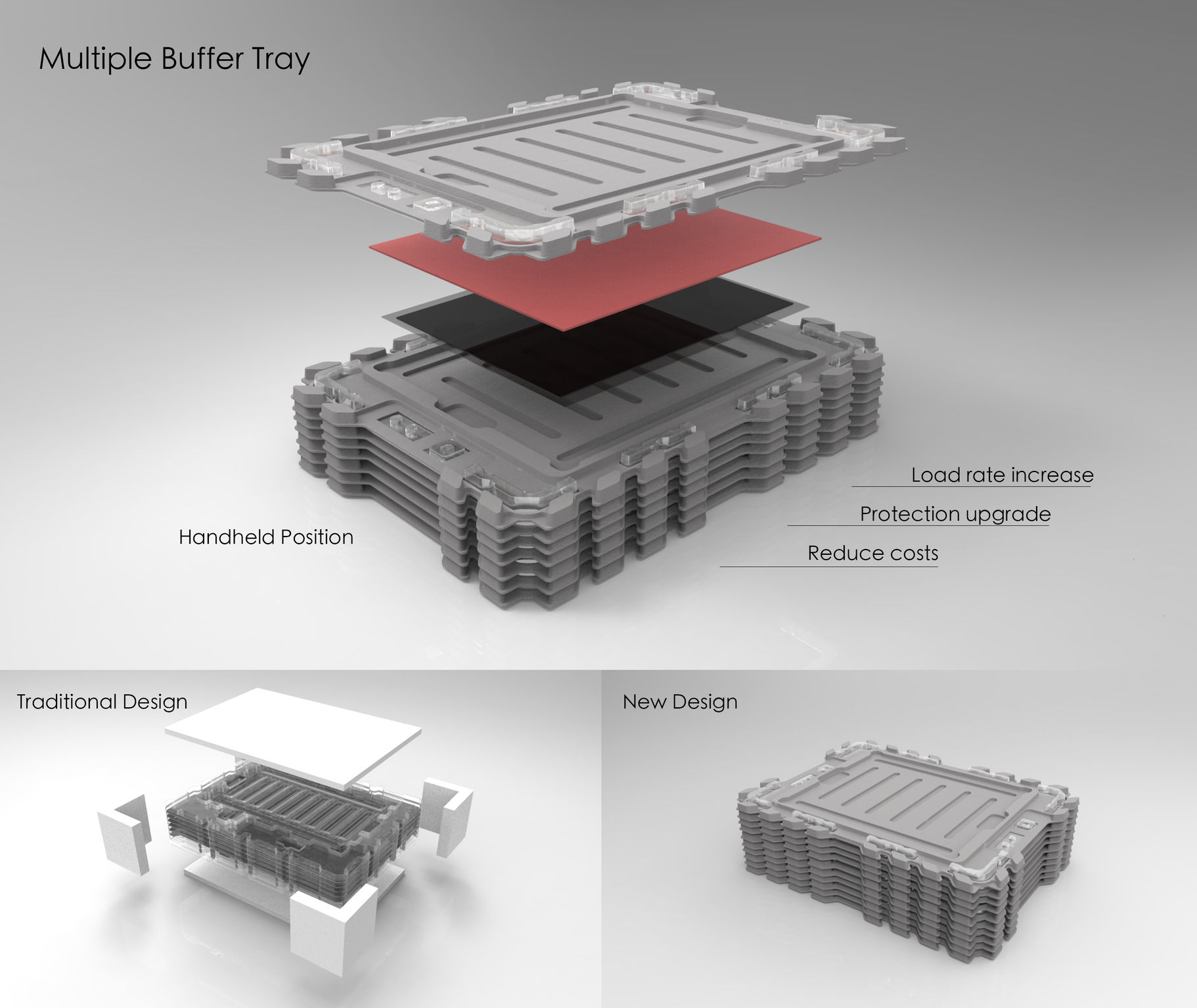

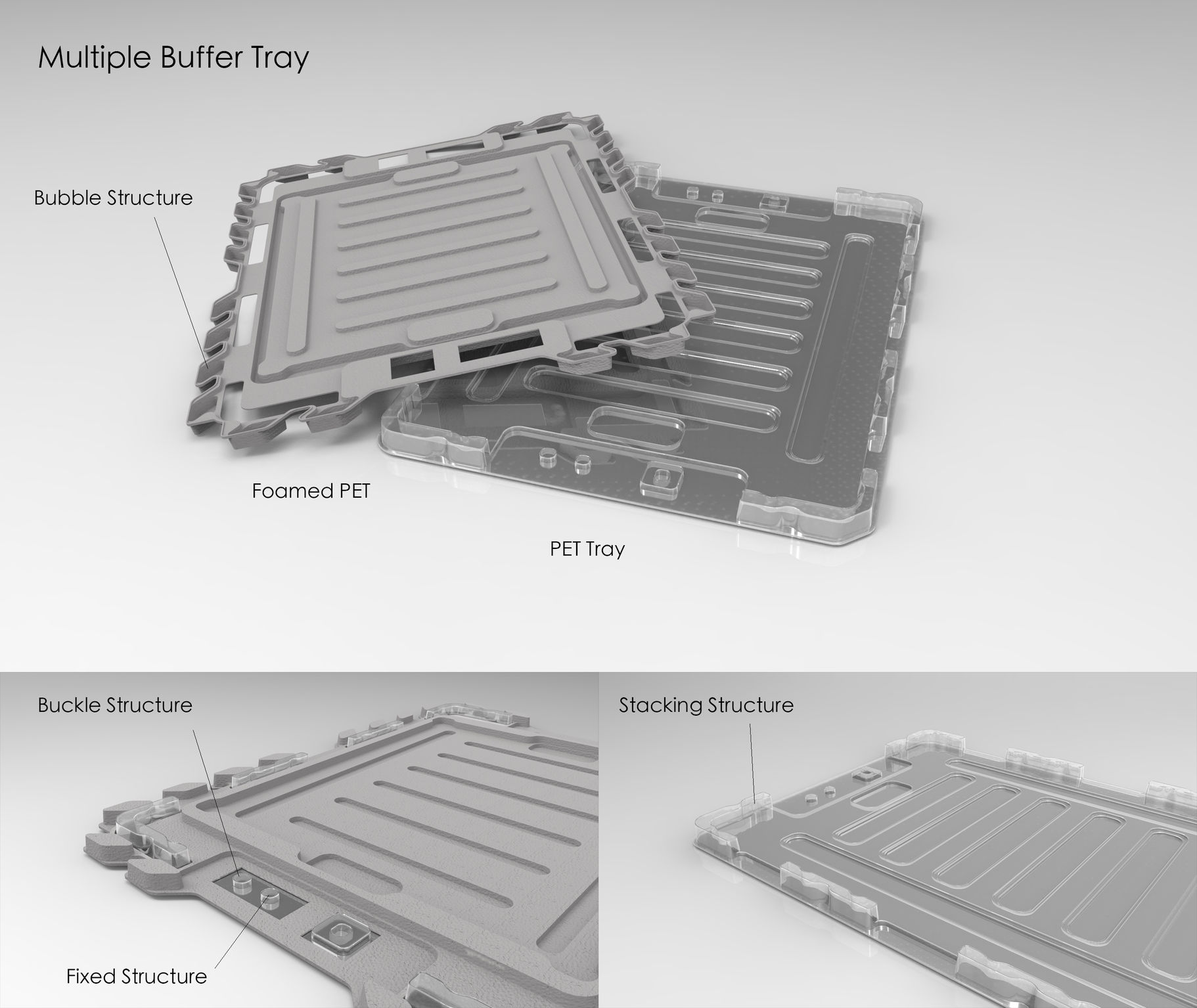

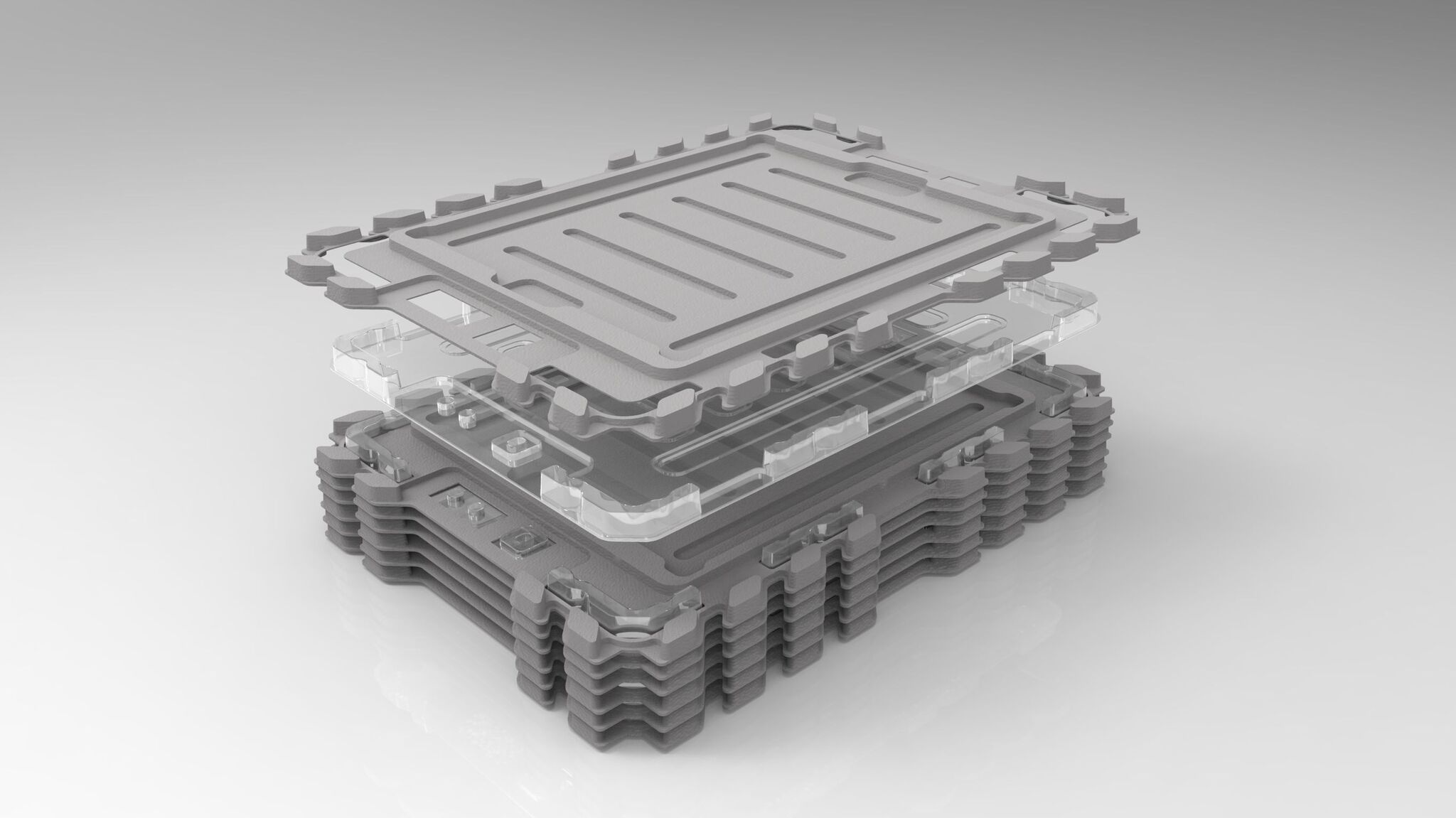

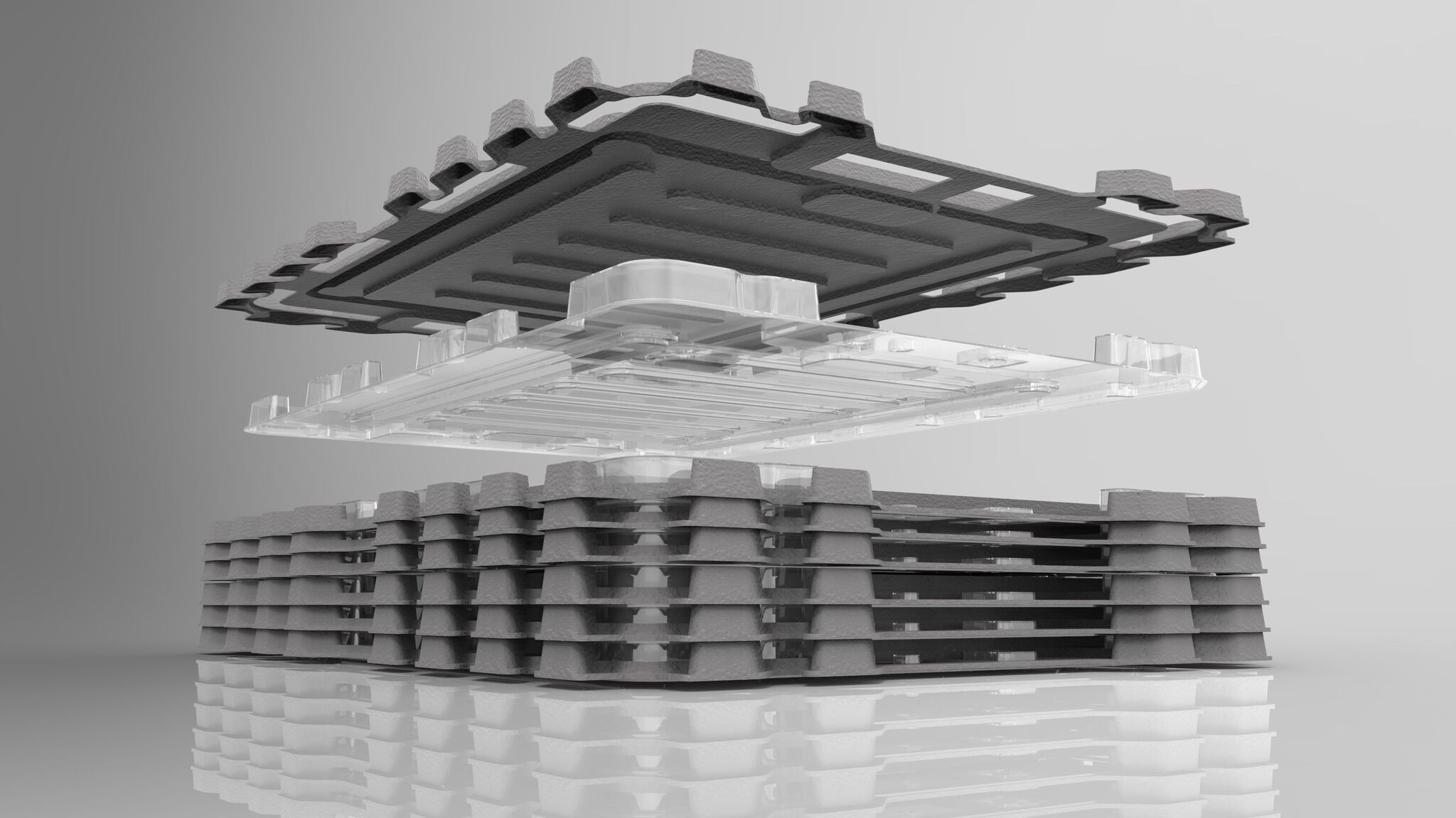

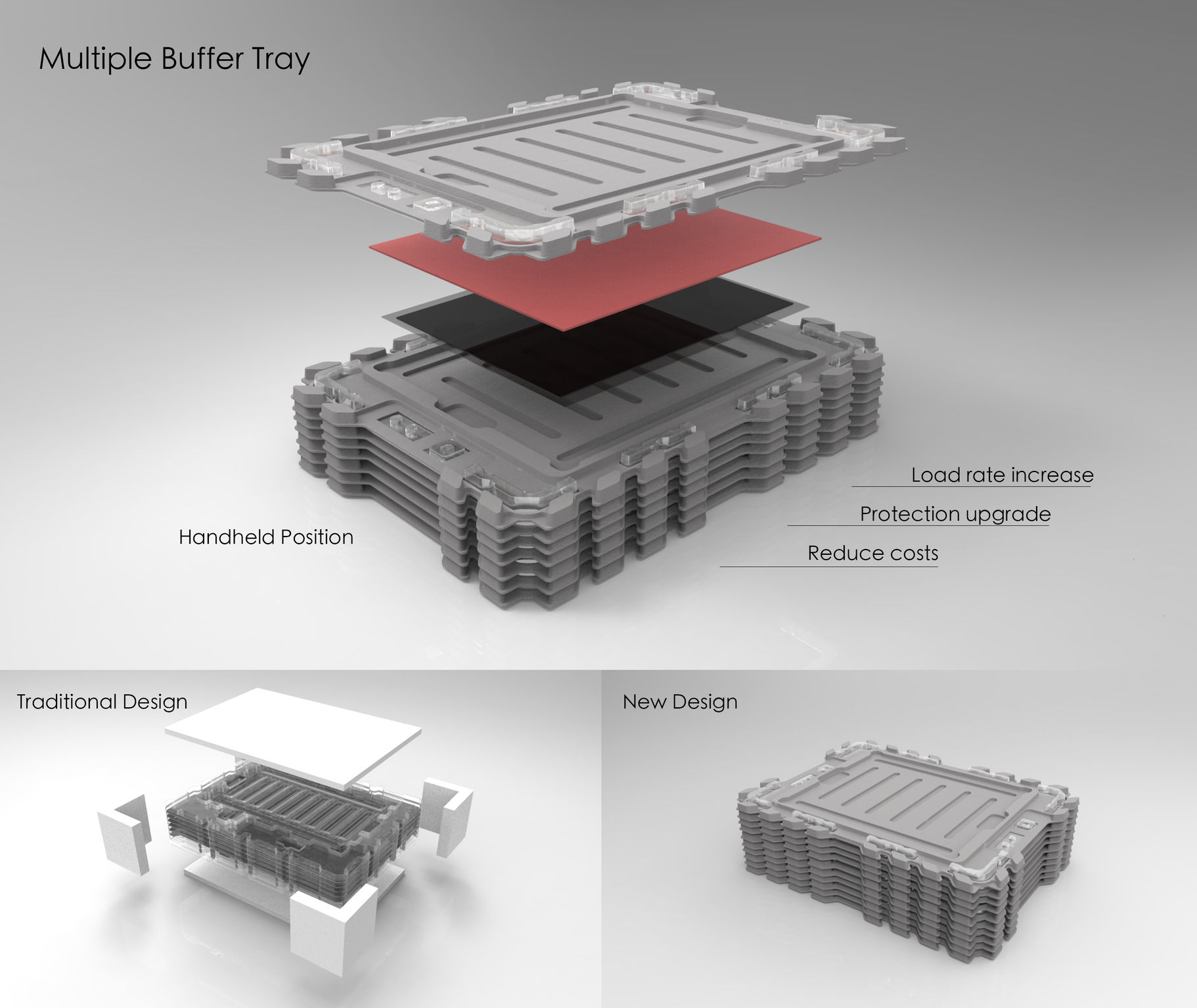

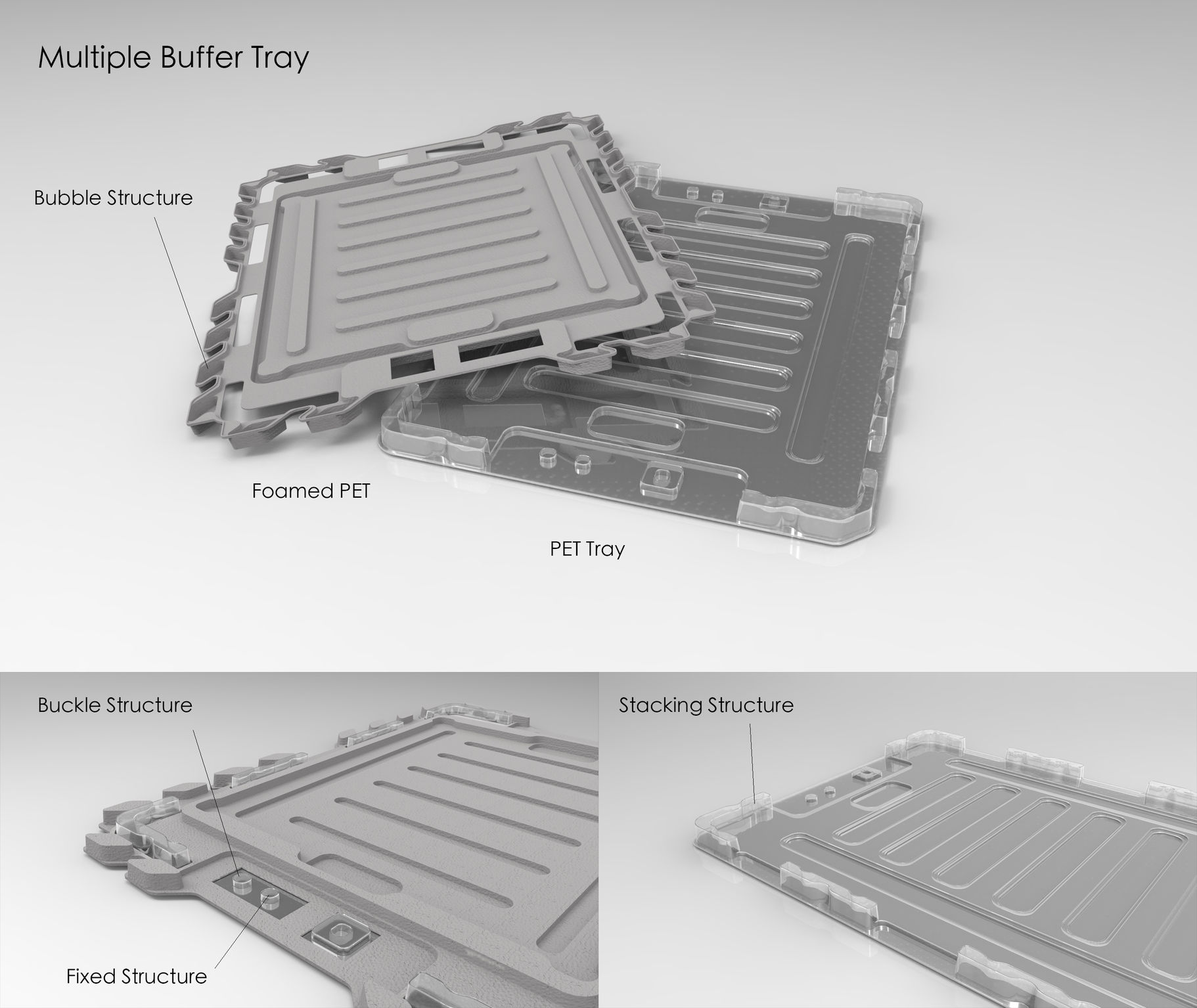

Multiple Buffer Tray

Transport packaging

AU Optronics Corporation_master

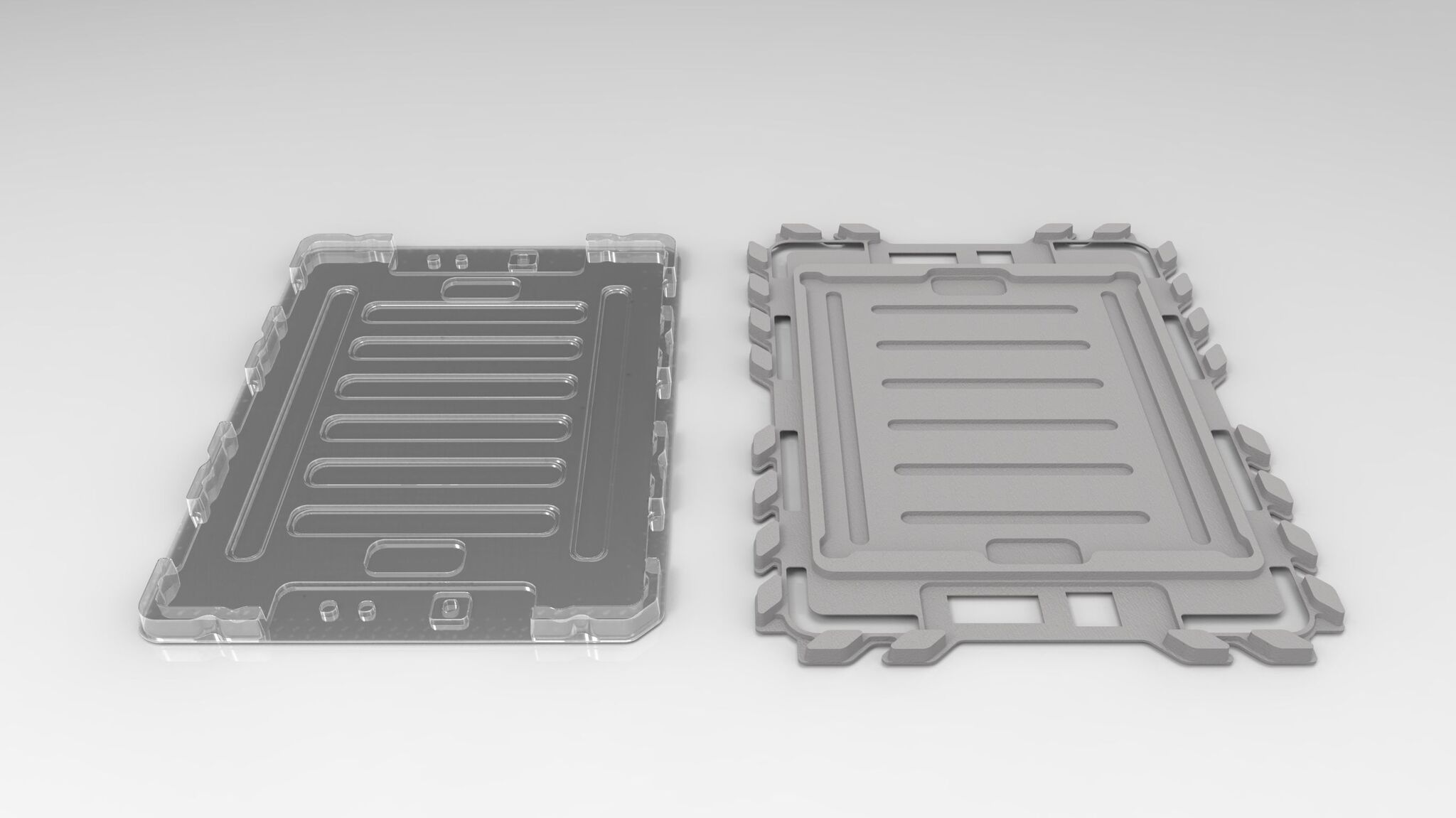

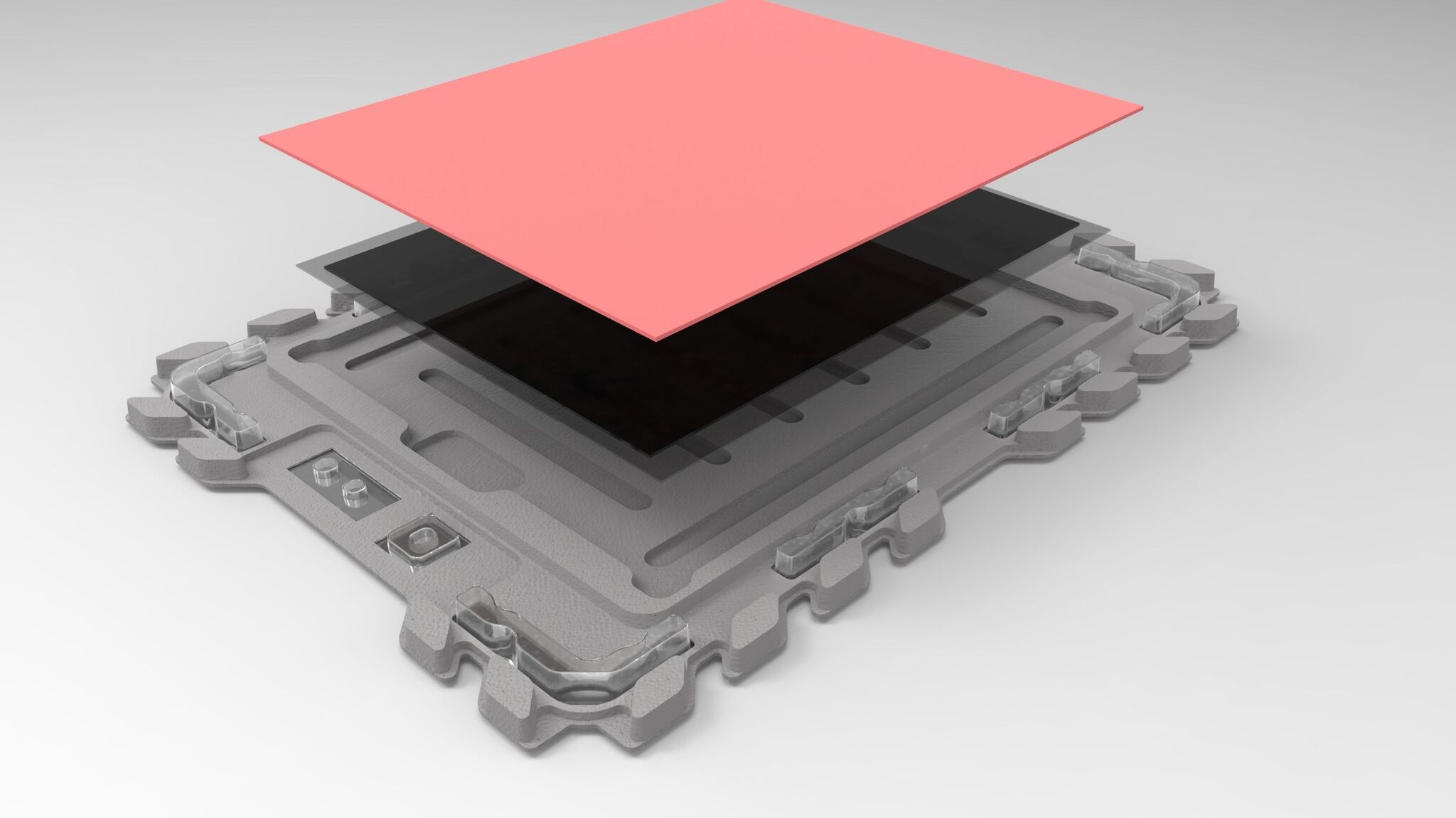

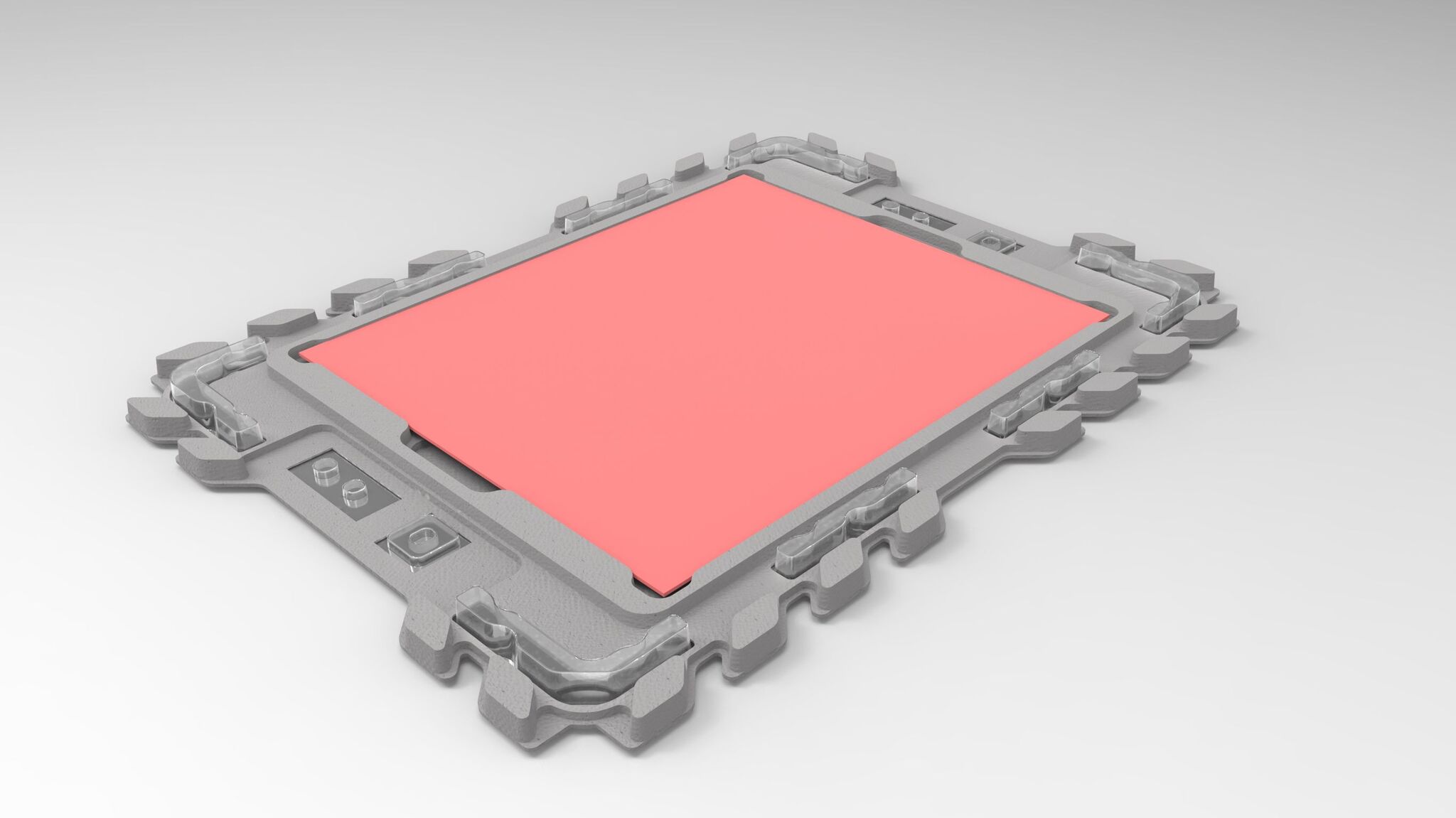

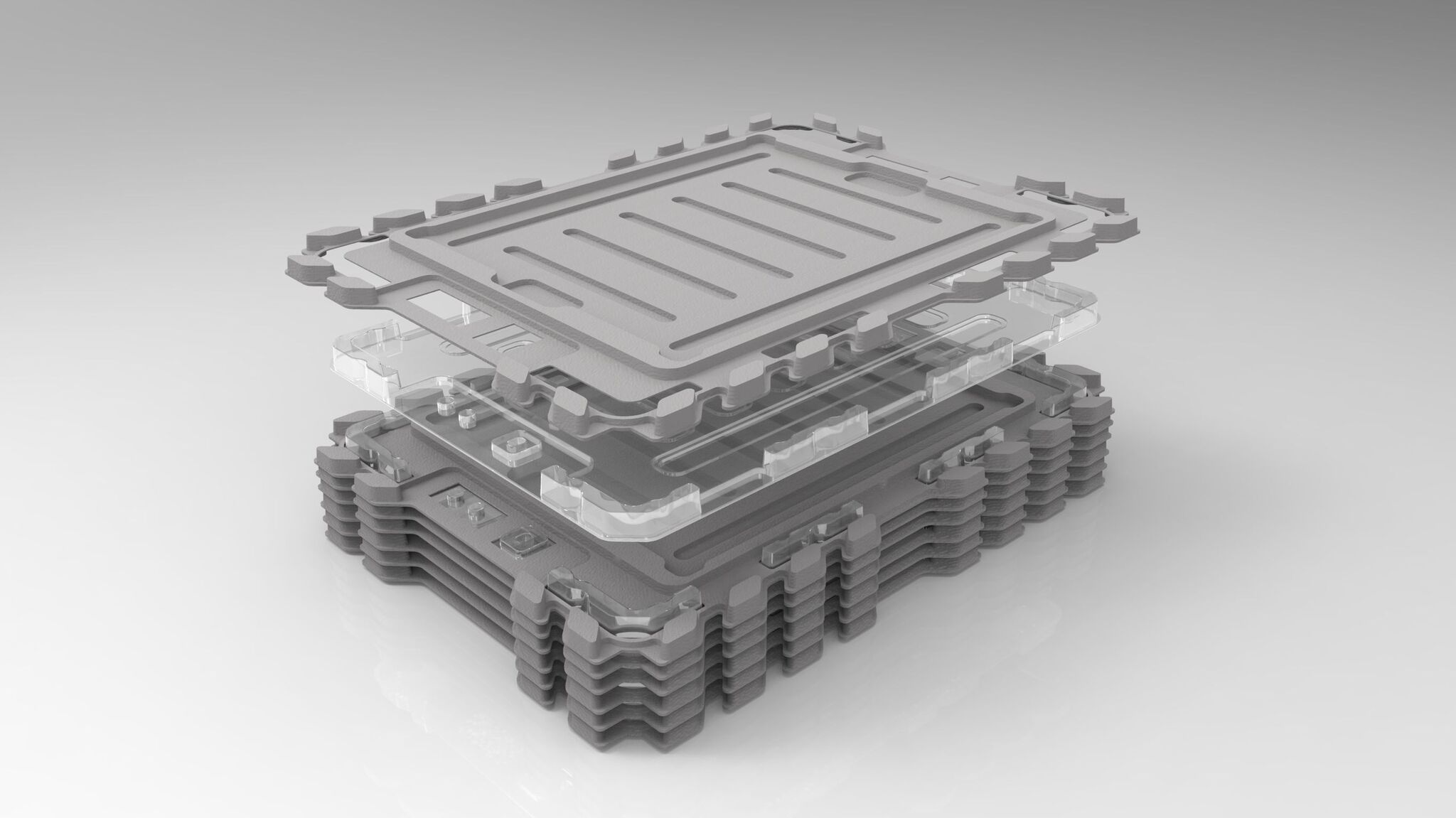

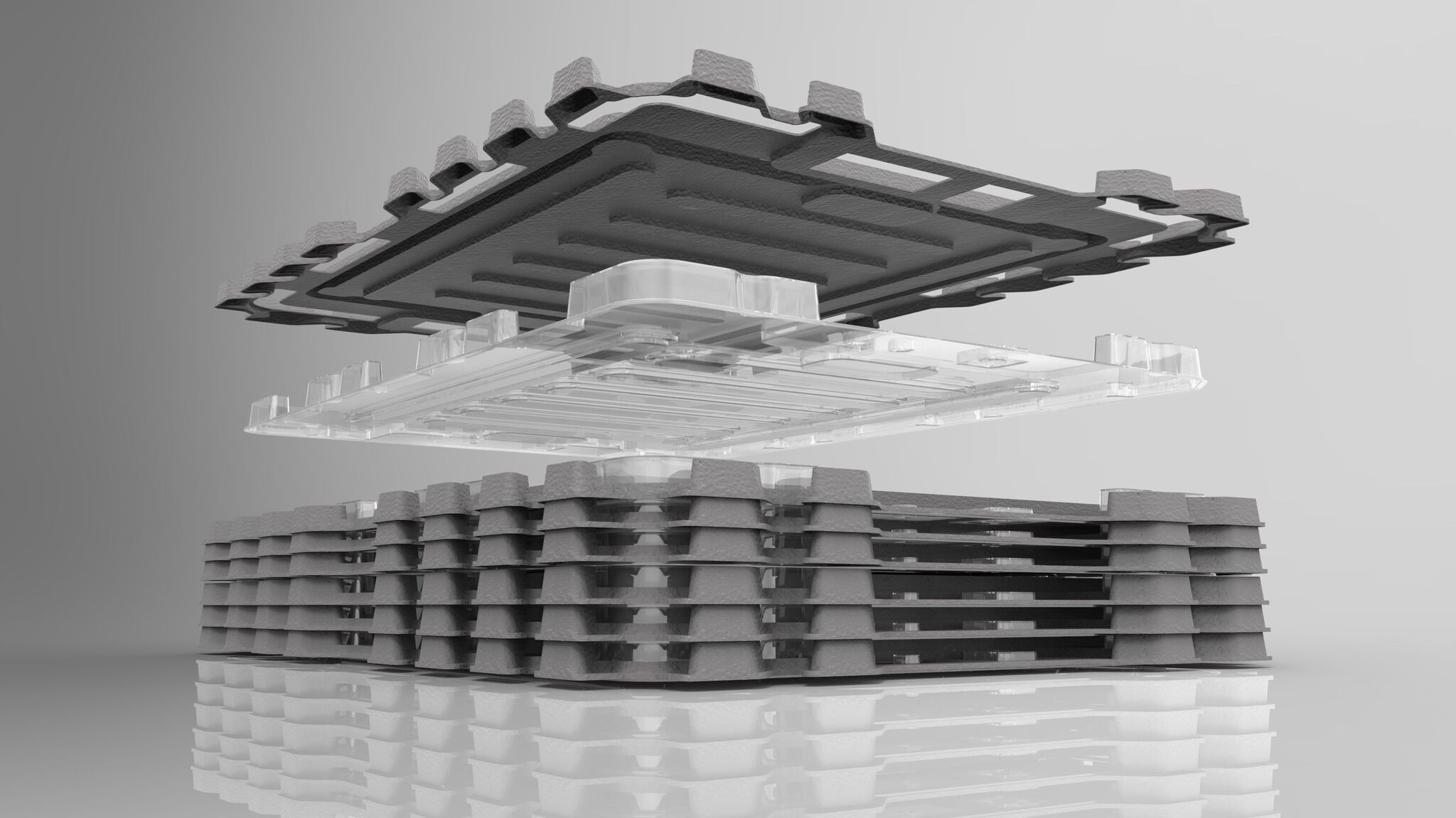

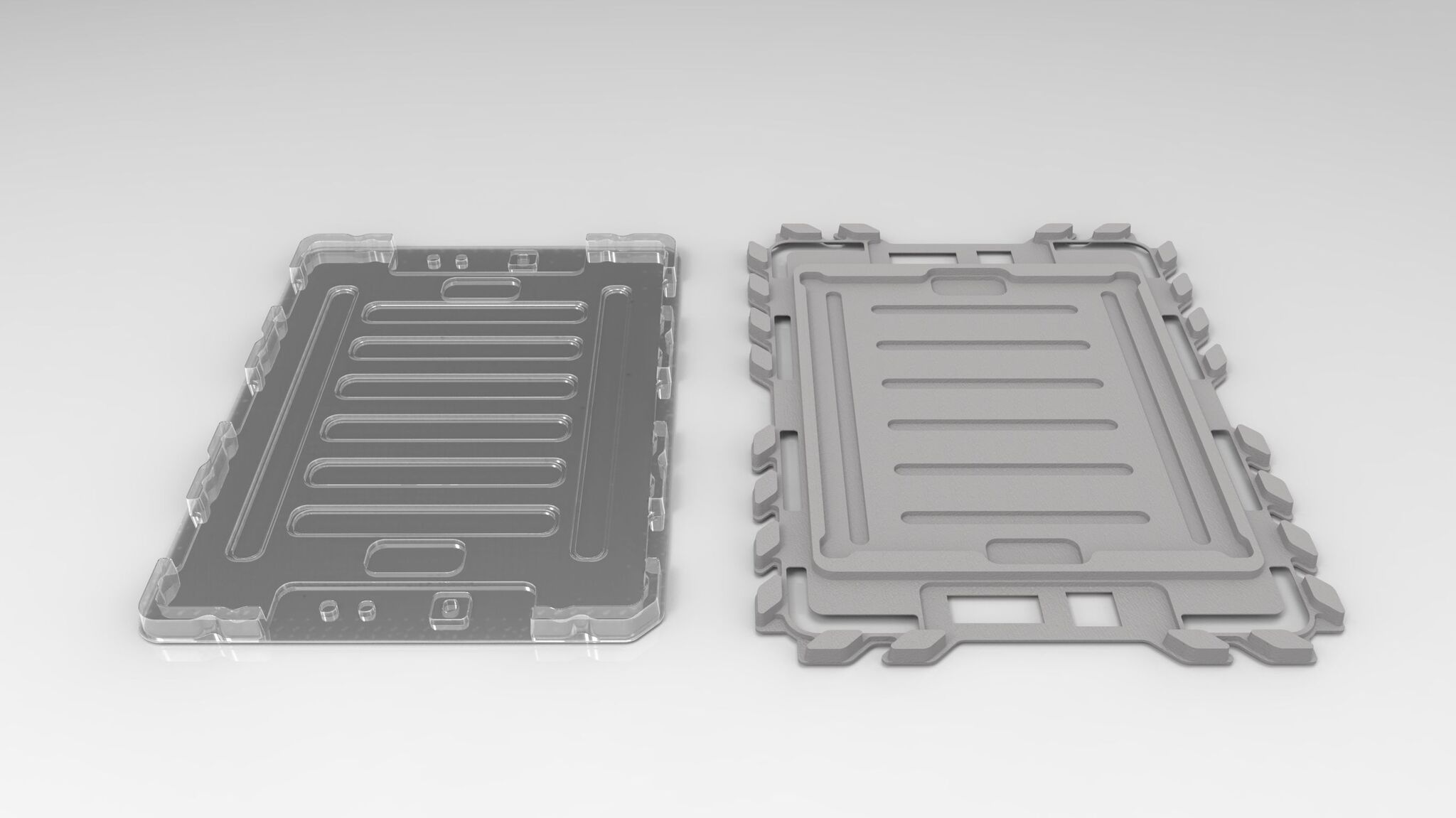

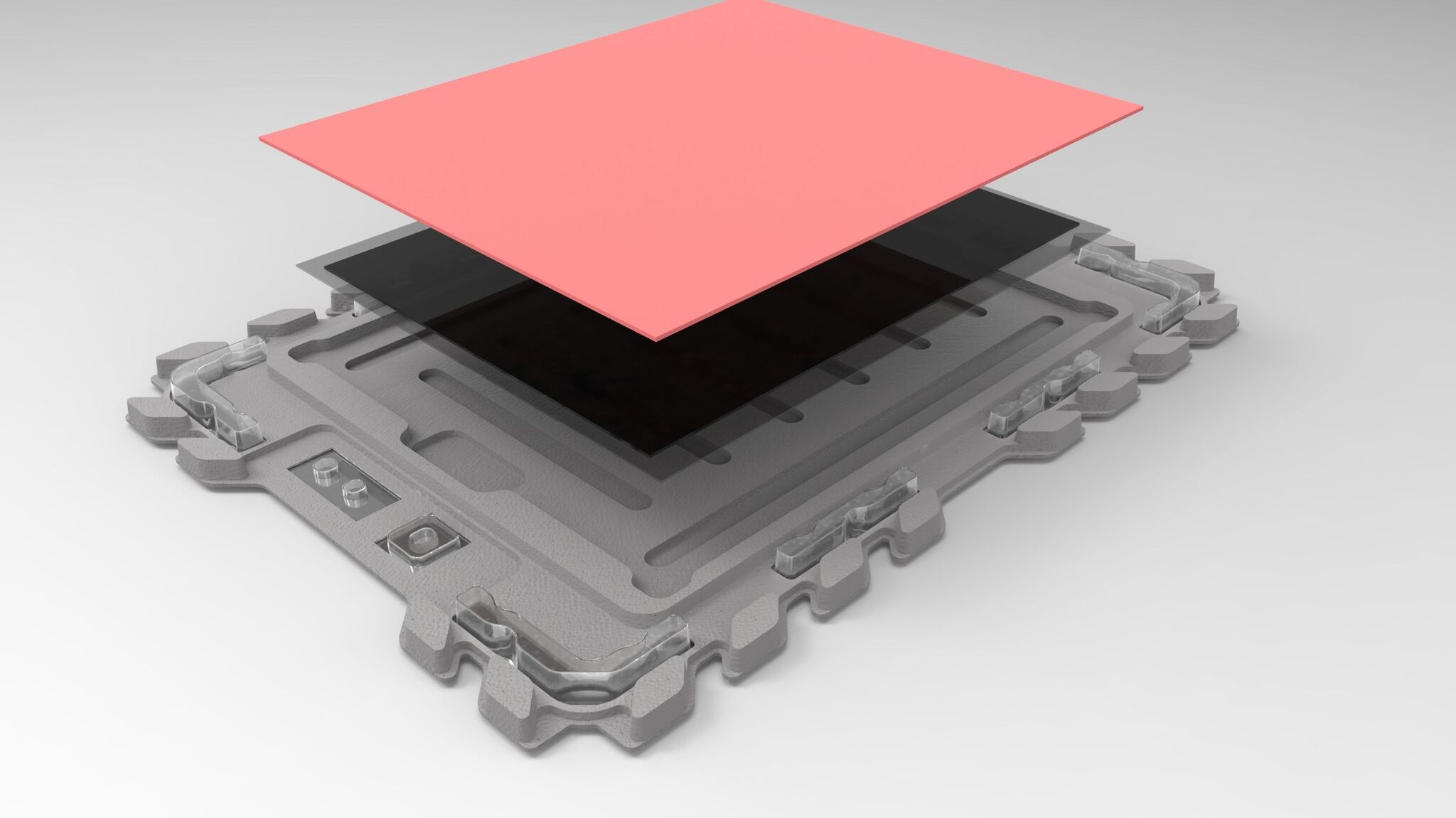

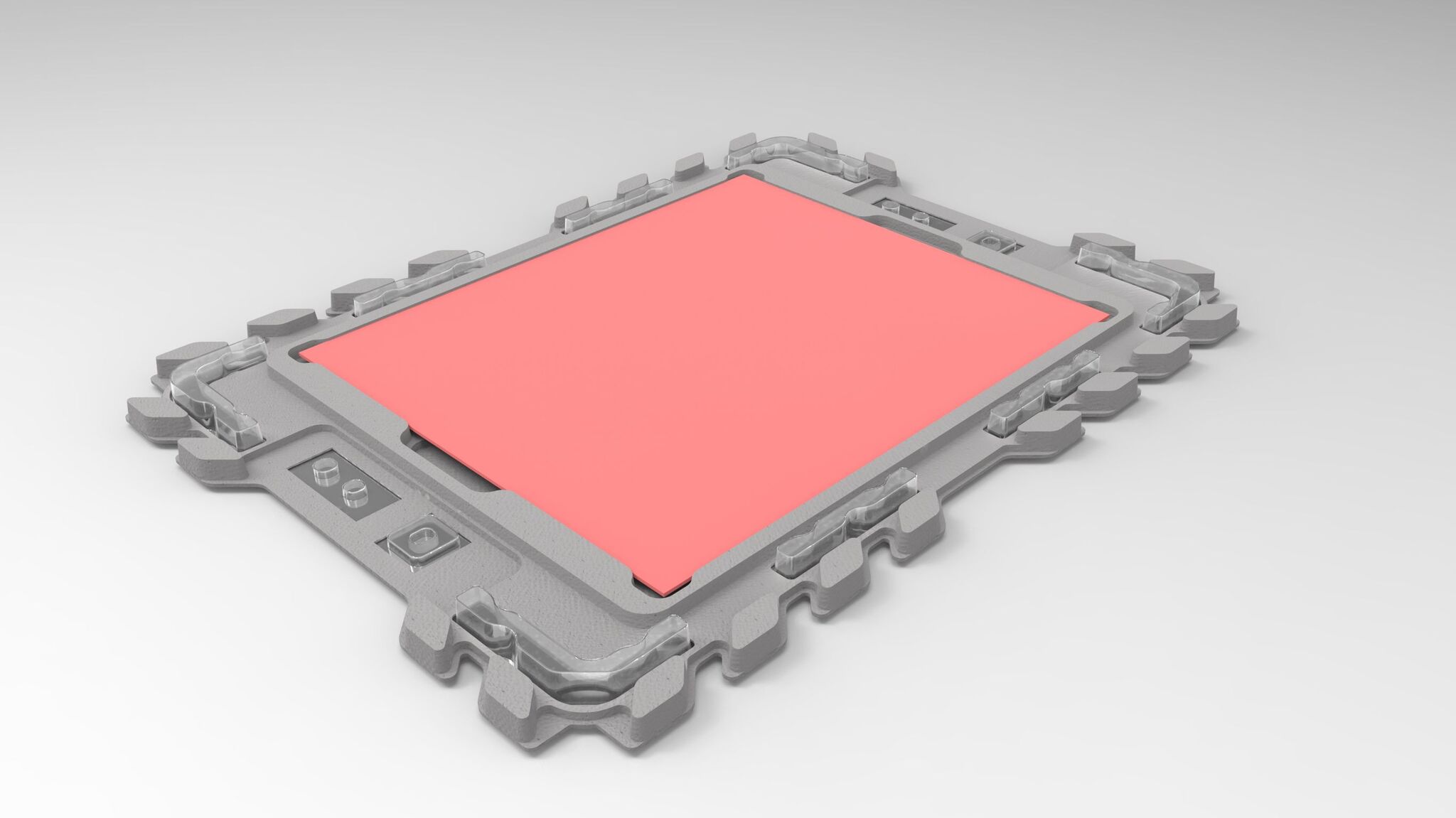

Panel development is becoming increasingly thin, especially in recent OLED and flexible products, traditional packaging has been unable to provide adequate protection. The new "Multiple Buffer Tray" design combines foamed PET on a conventional PET tray. Foamed tray is a soft material surrounding the product, and its bubble-like structure absorbing the impact can replace the cushion around. This significantly reduces the cost of materials, shortens the staff packing work and reduces the fragmentation caused by packing. PET tray can be reused for different inside diameters of foamed tray, reduces carbon emissions and saves mold development costs.

Client / ManufacturerDesign

AU Optronics Corporation_master

Hsinchu, TWAU Optronics Corporation_master

Hsinchu, TWDate of Launch

2016

Development Time

up to 12 months

Target Regions

Asia

Target Groups

Trade / Industry