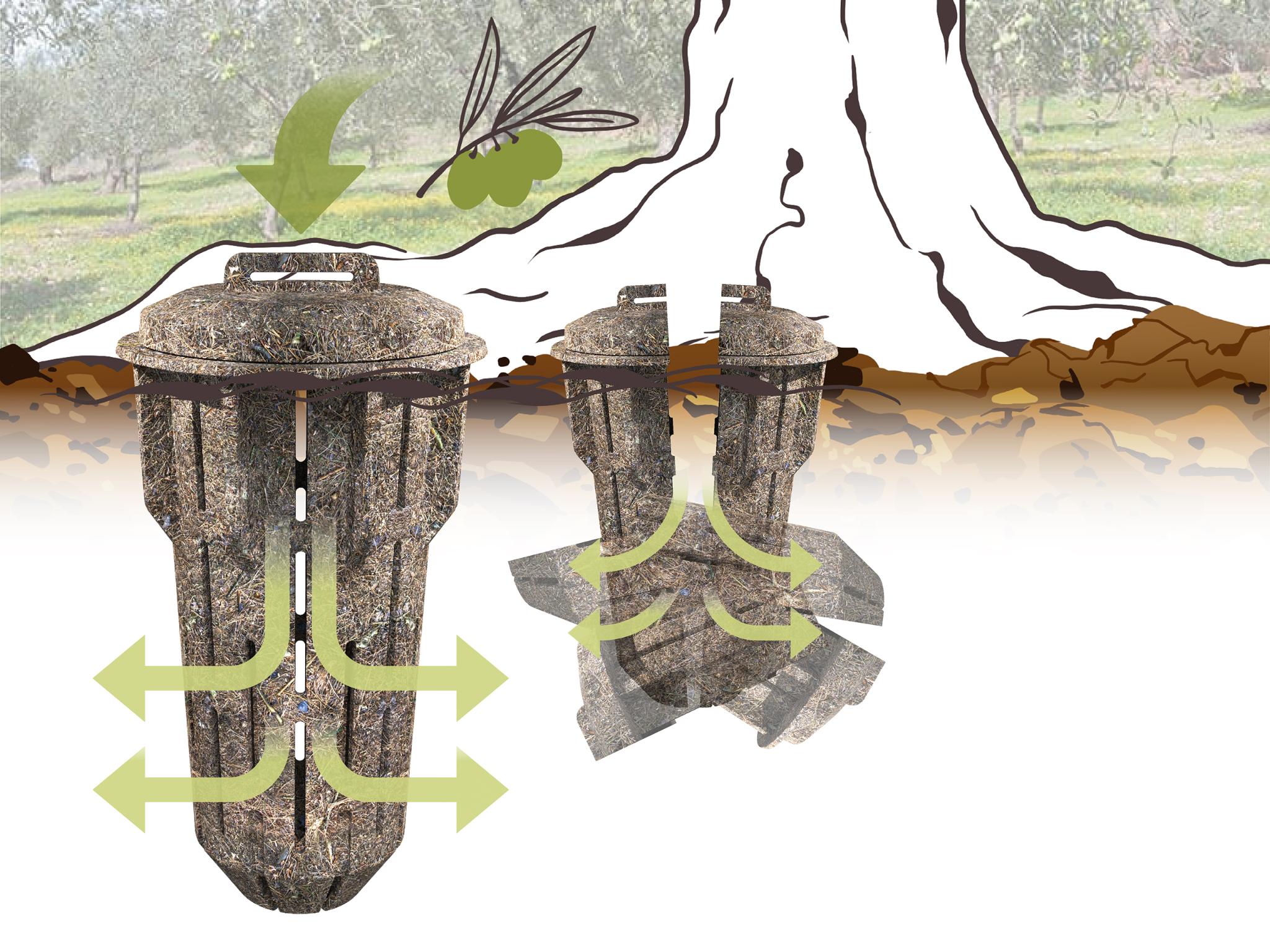

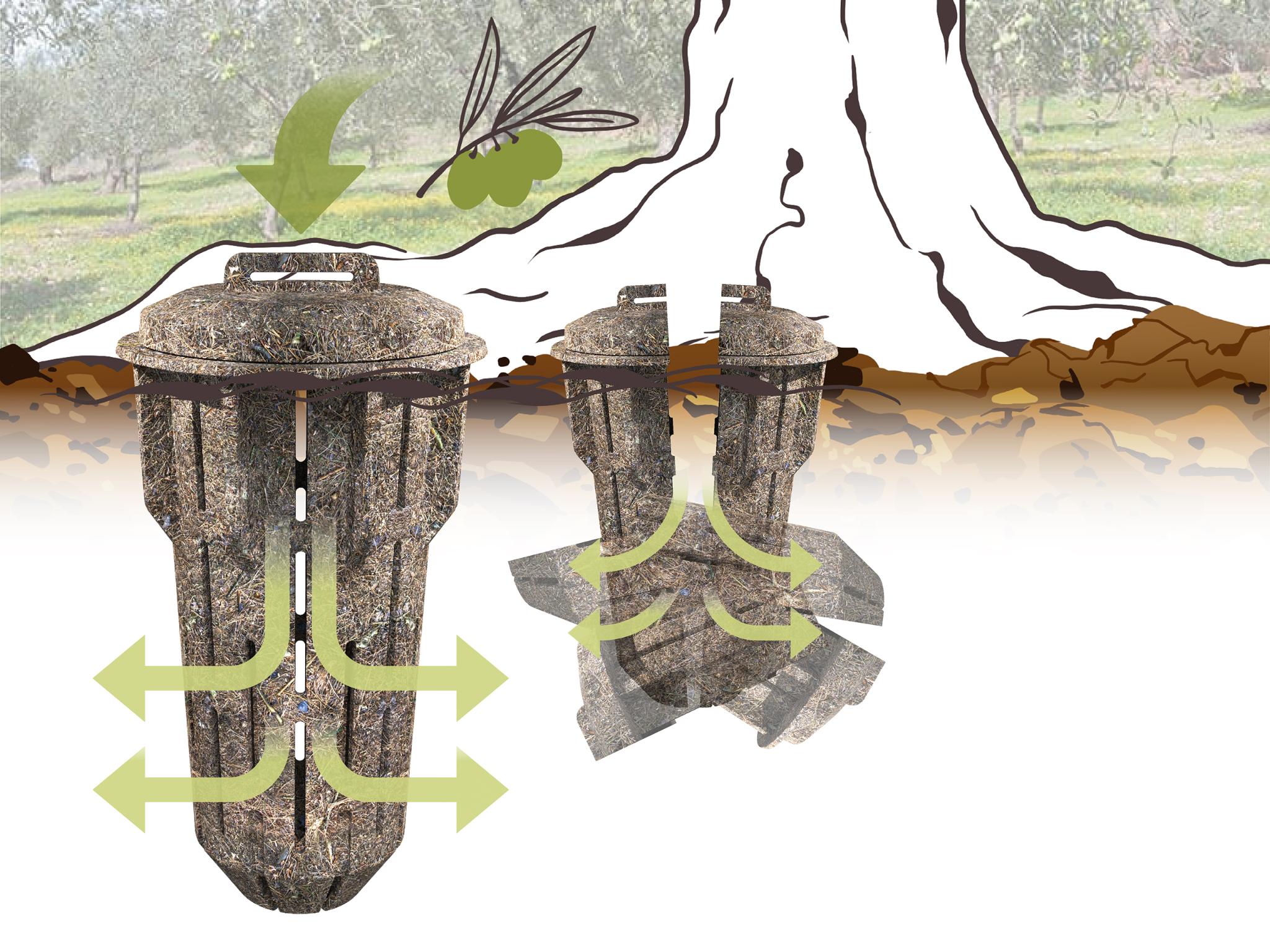

Mycelial Composting Tube

Composting Tube

KUN DEA MACHINERY CO., LTD.

Mycelial Composting Tube is crafted from waste generated during the cultivation of olive trees. Olive tree compost collected within the tube is processed with mycorrhizal fungi, white rot fungi, and other agents to decompose it into organic matter, serving as a nutrient source. The biodegradable tube follows a circular fertilization method, integrated with CRZ to establish mycorrhizal symbiosis. This enhances nutrient absorption, improves soil structure, and boosts resilience to environmental stress. During the various stages of olive trees, microbial agents or plant waste can be added to fulfill the requirements for different elements.

Client / ManufacturerDesign

KUN DEA MACHINERY CO., LTD.

New Taipei City, TWNational Taipei University of Education

Taipei, TWDesigned by Chuang Chu-An, Li Chih-Yun, Wu Yi-Chen, Chen Zih-Jin, Lin Yu-He Advised by Prof. Li Kai-ChuOh! Design Studio

New Taipei City, TWIndustry-Academia Cooperation with Oh! Design Studio Chieh-An Chung, Zi-Shan ZhangDate of Launch

after 2025

Development Time

up to 12 Month

Target Regions

Australia / Oceania, Europe, North America, South America

Target Groups

Consumers / Users, Public Sector / Government