WLX - Conveyor for food

Conveyor

FlexLink AB

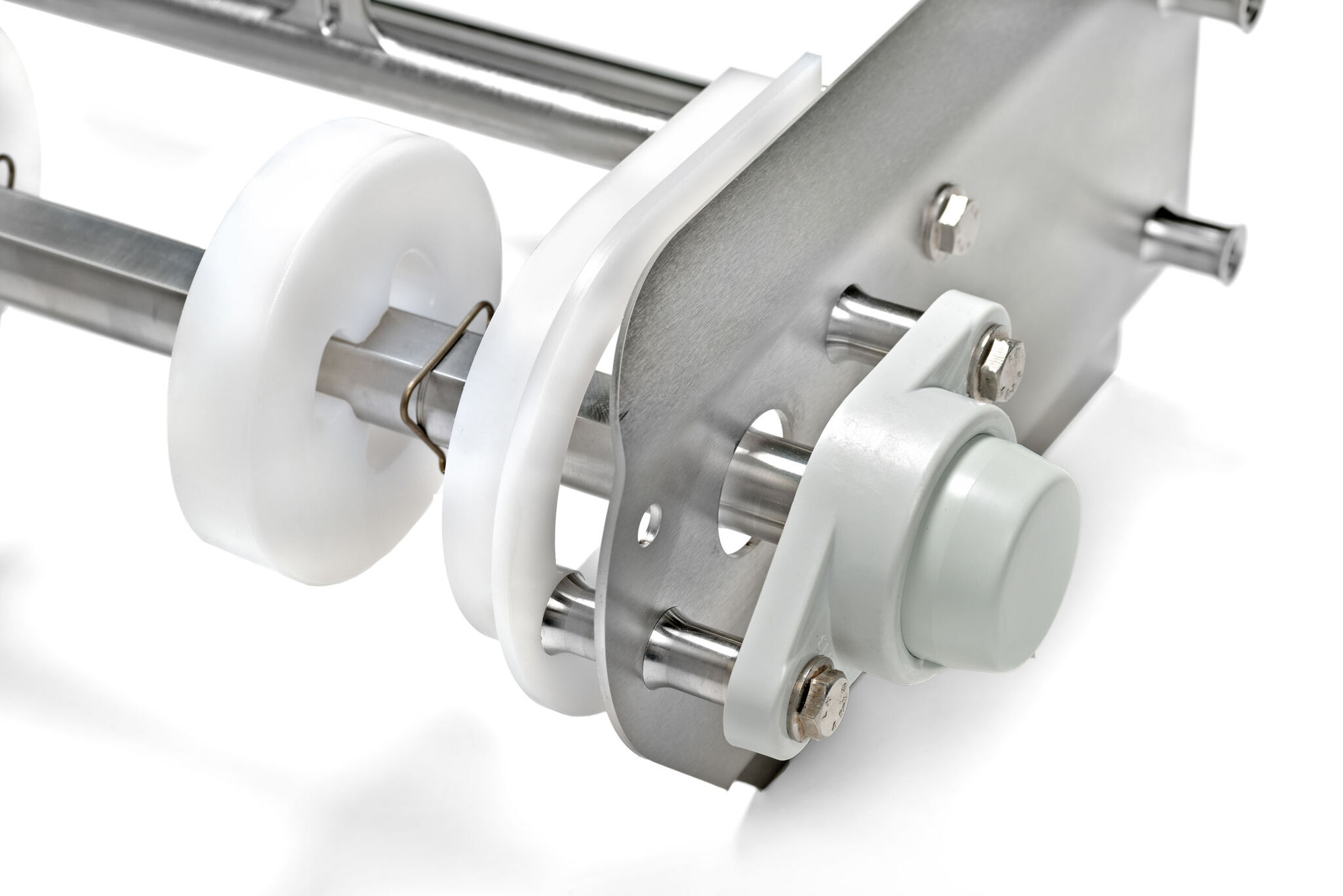

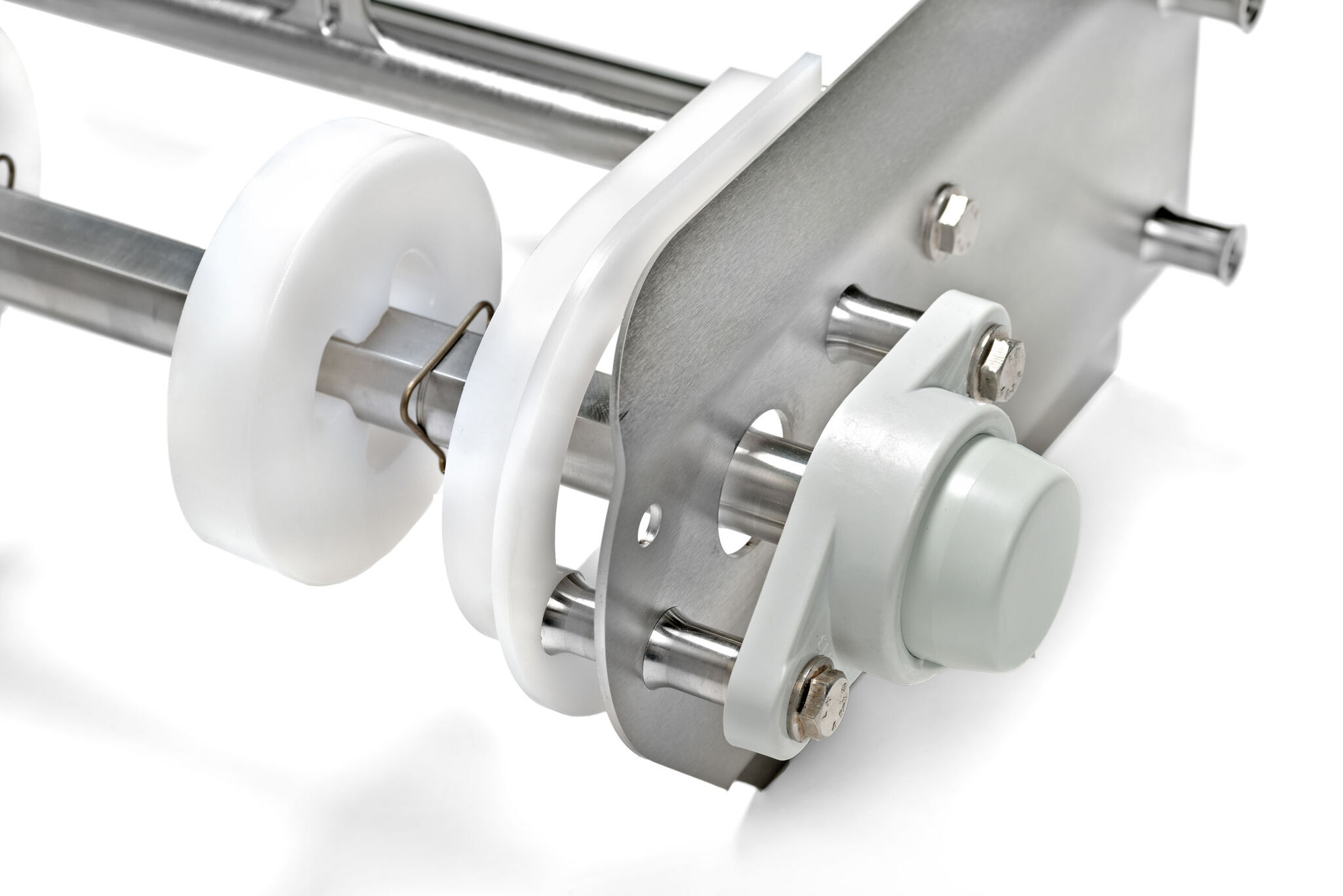

The WLX wide belt conveyor is safe, clean and reduces the total cost of ownership. It adheres to EHEDG hygienic design guidelines and is 3-A qualified to standard 75-01. The design facilitates simple cleaning procedures and ensures a consistent result. The hygienic design features sound hygienic practices, with rounded corners, no metal to metal contact and no flat surfaces. Hollow bodies and crevices, where pathogens and contaminants tend to get trapped, are eliminated. Operator safety is prioritized by eliminating pinch points and sharp edges, and operability is enhanced with belt lifting tools and low noise levels.

Client / ManufacturerDesign

FlexLink AB

Göteborg, SEFlexLink AB

Göteborg, SEDate of Launch

2014

Development Time

13 - 24 months

Target Regions

Africa, Asia, Australia/Oceania, Europe, North America, South America

Target Groups

Trade / Industry