Verbundwerkstoff/composite material

Composite metal / glass bubbles

Fraunhofer Institut für Fertigungstechnik und angewandte Materialien

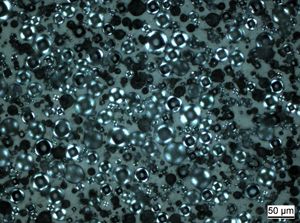

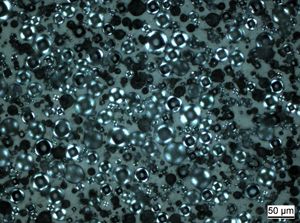

This material is a composite produced by casting techniques and based on metals and microscopic small glass bubbles. The maximal size of the glass bubbles is 60 microns. The material can be cutted easily. It has a metallic look and a metallic touch but on the same time a significantly reduced density. For instance the density of aluminium is reduced from 2,7g/cm3 to 1,2g/cm3 and the density of zinc from 7g/cm3 to 3,1g/cm3. The closed microscopic-scale porosity of the material allows the application of various coating technologies - from dipvarnishing to electroplating - which are not possible for most other porous materials. An example for that is the production of weight-reduced chromium-plated zinc components.

iF Gold Statement

Materials Look & Feel – selected by Aart van Bezooyen

This composite material produced by using casting techniques and microscopically small glass bubbles with a maximum size of 60 microns provides totally new fields of application. It is 50% lighter than comparable metal pieces and has special characteristics in terms of touch and visual appearance. The jury considers this material to be both a potential substitute for aluminum and a pioneering development in the field of materials.

Client / ManufacturerDesign